Hot rolled steel is a versatile material that has a wide variety of applications across various industries. As one of the most commonly used materials in the construction sector, hot rolled steel is used to produce different structural shapes such as steel beams, channels, and angles.

Steel beams are among the most widely used structural components in the construction industry, primarily because of their strength and durability. They are often used to support heavy loads in buildings, bridges, and other structures. Hot rolled steel beams are produced through a process that involves heating a billet of steel to very high temperatures, then rolling it into the desired shape.

Another popular structural steel component is the A36 structural steel channel. This hot rolled mild steel C-shaped beam is commonly used to support walls, roofs, and ceilings in commercial buildings. A36 structural steel channel is highly resistant to corrosion and can withstand heavy loads without bending or buckling.

Steel angles are another category of hot rolled steel products that are widely used in the construction industry. They are commonly used for framing and reinforcement purposes in building construction. Steel angles are manufactured through a process that involves hot rolling a steel billet into the desired shape, typically an L-shape or a T-shape.

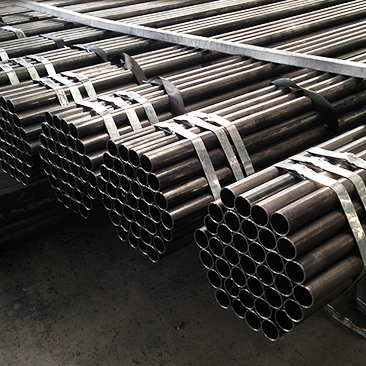

In addition to the construction industry, hot rolled steel is also used in the automotive, energy, and manufacturing sectors. It is often used to produce a wide range of components for various applications, including the manufacture of pipes, tubing, and engine parts.

Overall, hot rolled steel is an incredibly versatile and universally applied industrial material that plays a key role in many different industries. Its strength, durability, and resistance to corrosion make it an ideal option for a wide range of applications, from heavy structural support to intricate manufacturing components. As such, it remains a crucial component in the modern world, providing strength and support for a wide range of essential applications.